There is a virus running through this world, threatening to destroy all quality circuit boards. As devices get smaller and smaller and pitches get tinnier and tinnier, more and more board fabricators are taking the easy road out and refusing to put solder mask dams between the copper pads of fine pitch devices. We must end this virus in its tracks before it threatens the entire eco-system of manufacturable boards!

When designing products with 0.5mm or even 0.4mm pitch QFP and QFN style devices, please use the following design rules. Then please insist with your PCB fab to meet these design requirements. They may not like it, but they’re fully capable of producing it.

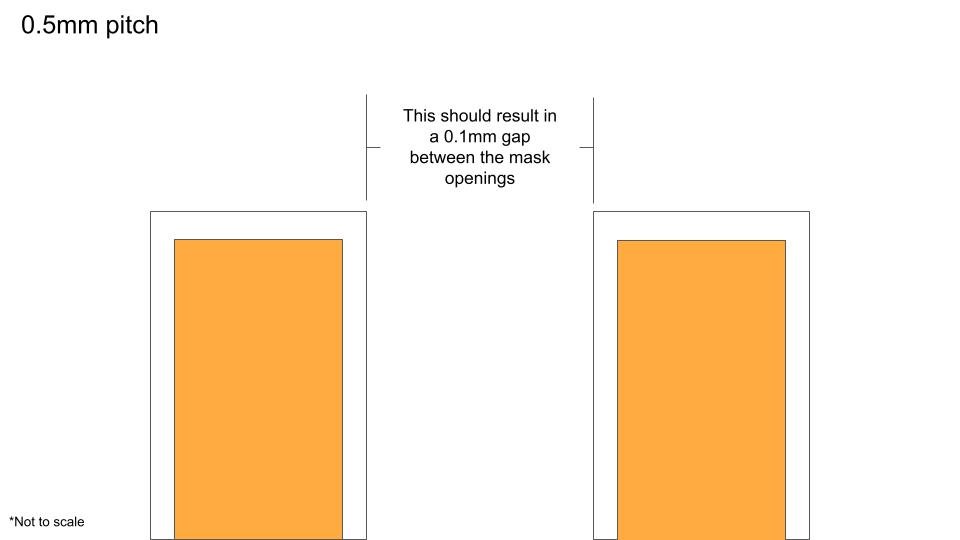

When designing for a 0.5mm pitch device, please use this copper width and this mask width.

The PCB fab will want to have at least 0.1mm gap between the mask opening to create a solder mask dam

The PCB fab will want to have at least 0.1mm gap between the mask opening to create a solder mask dam